Polymer Systems

Technology Limited

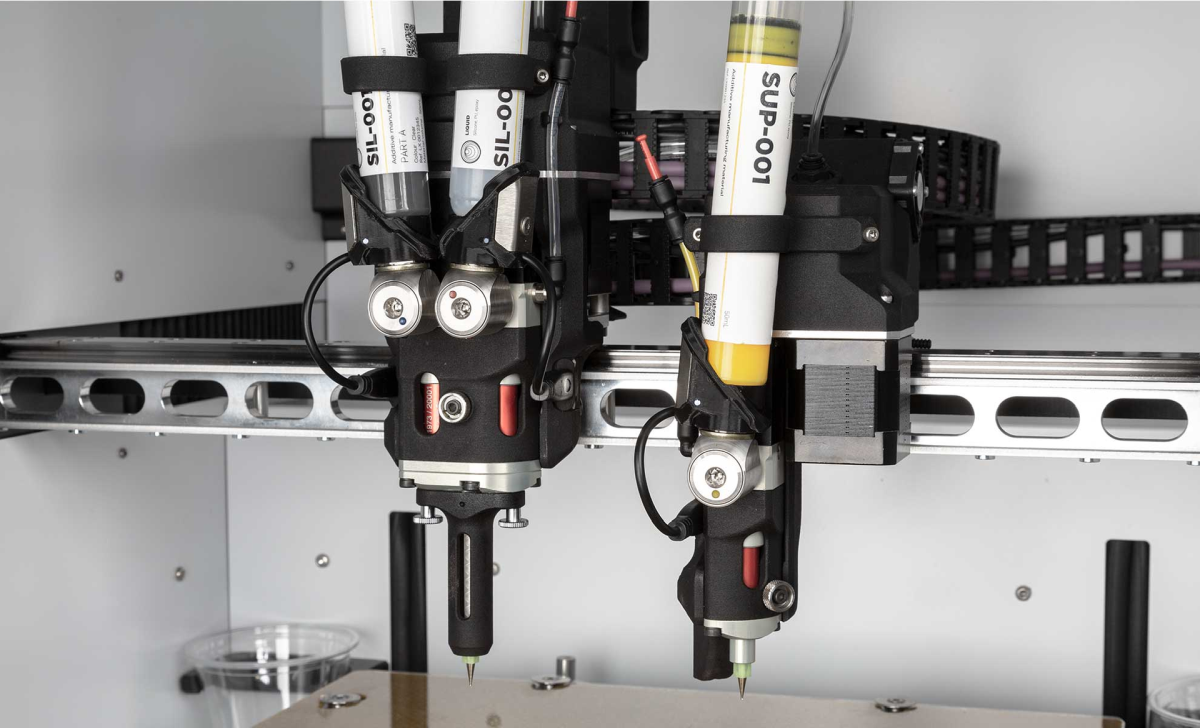

S300X

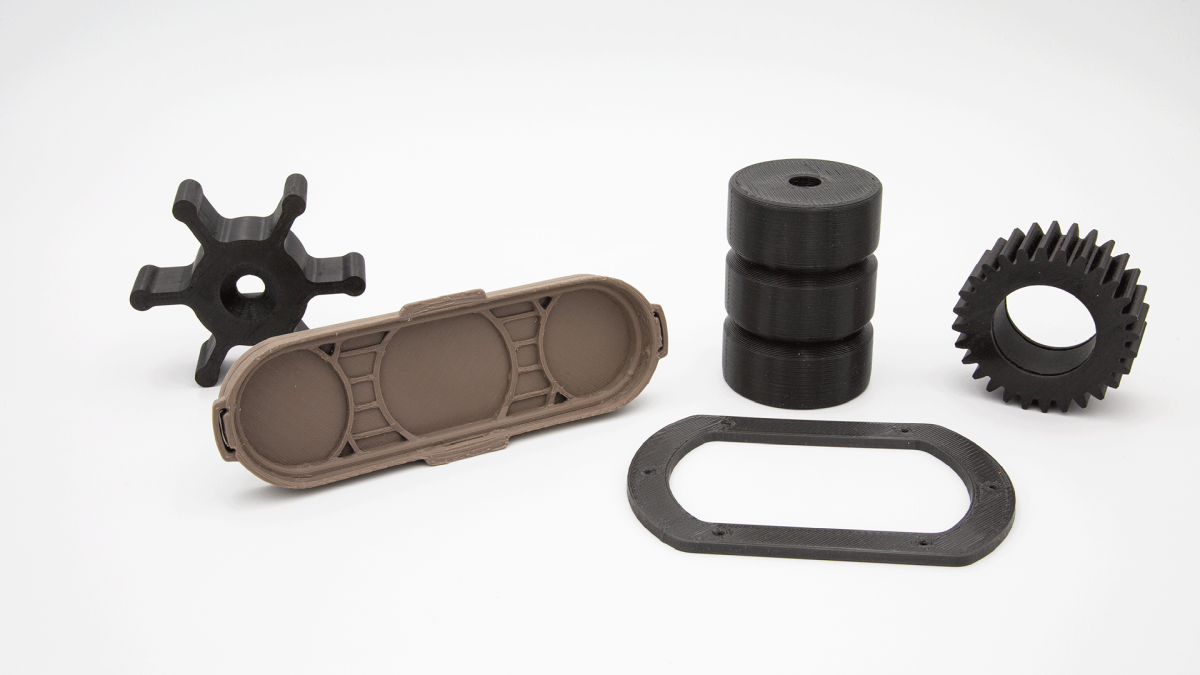

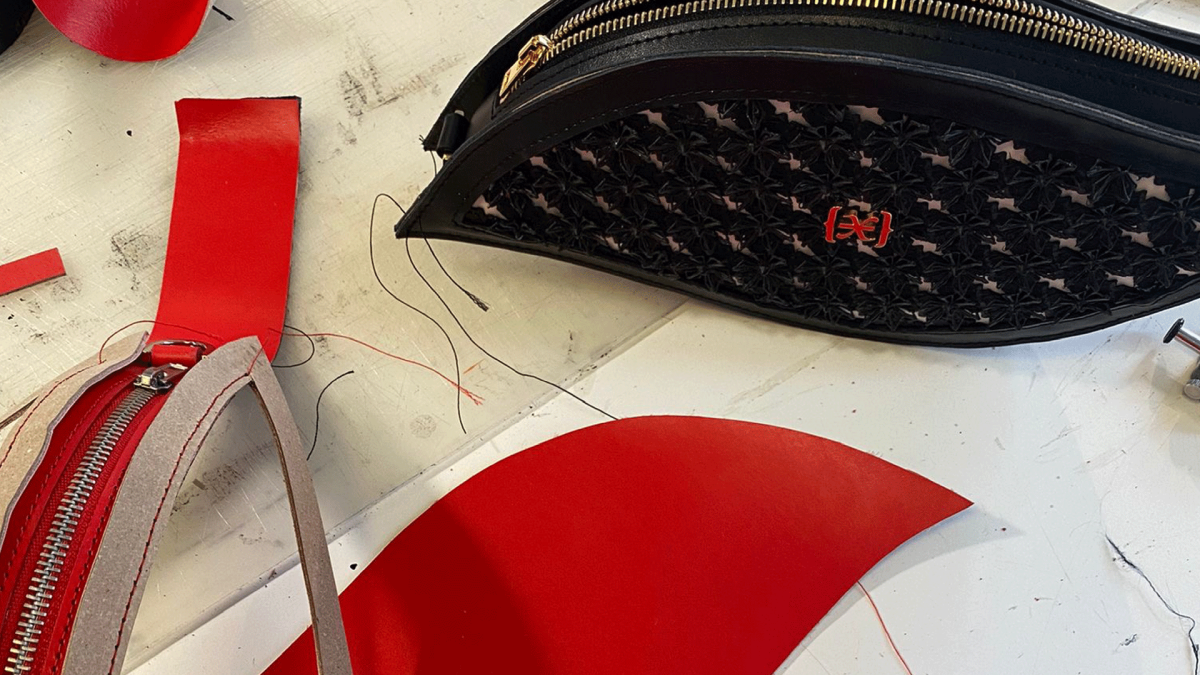

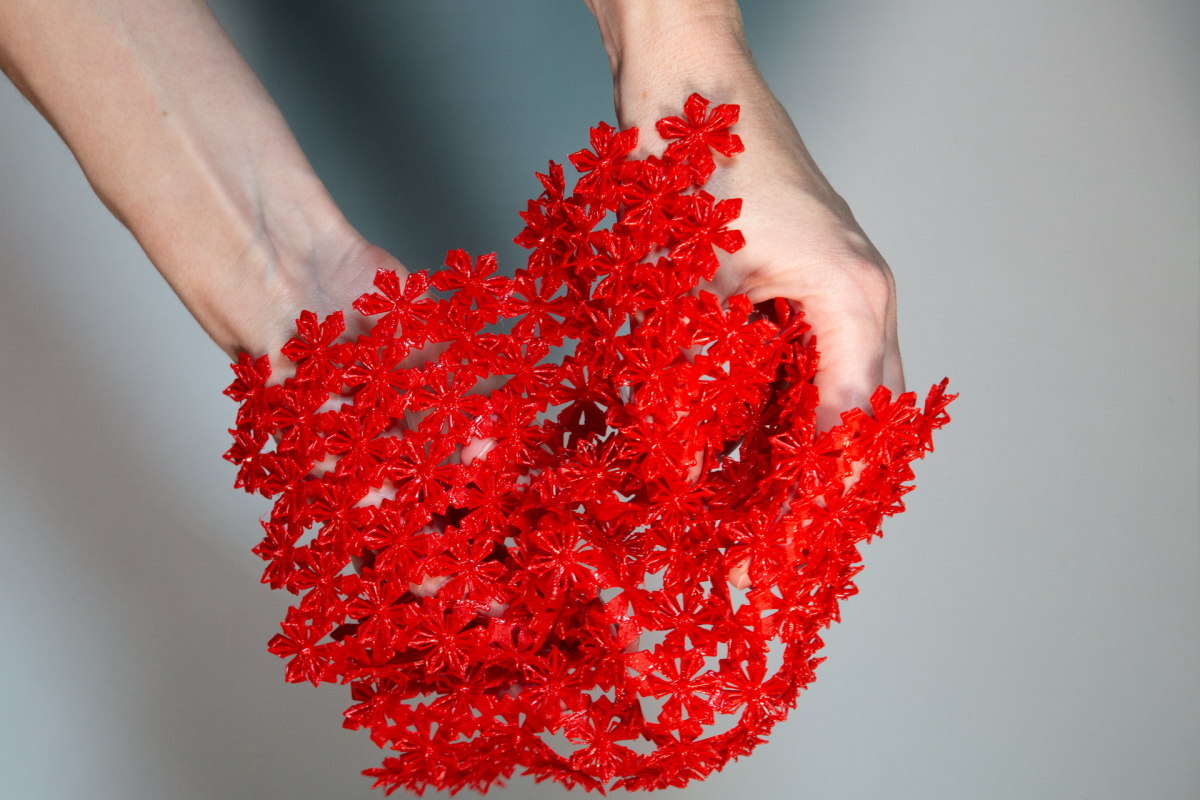

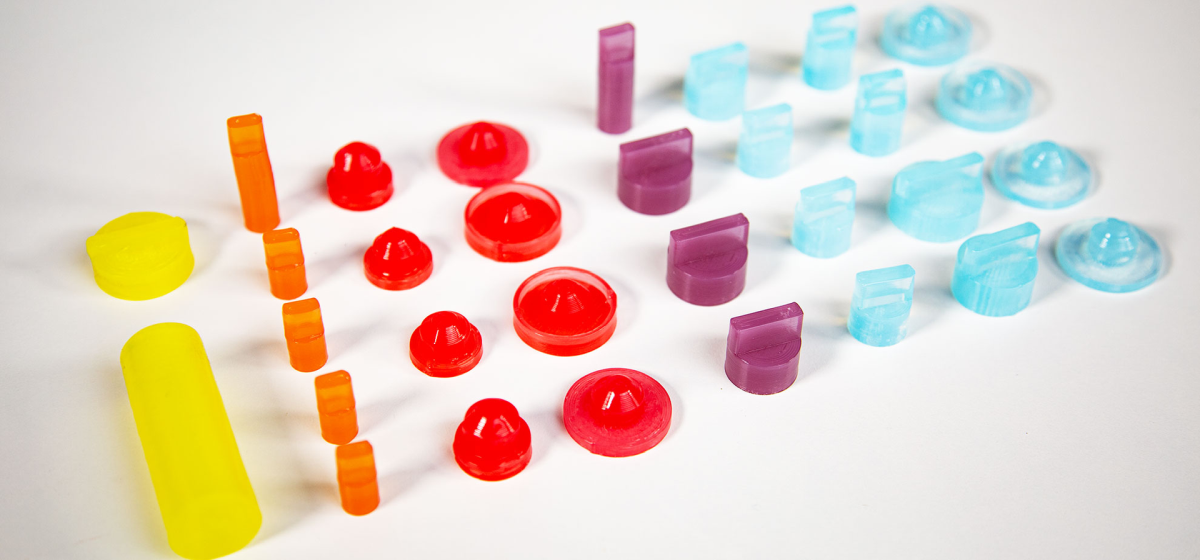

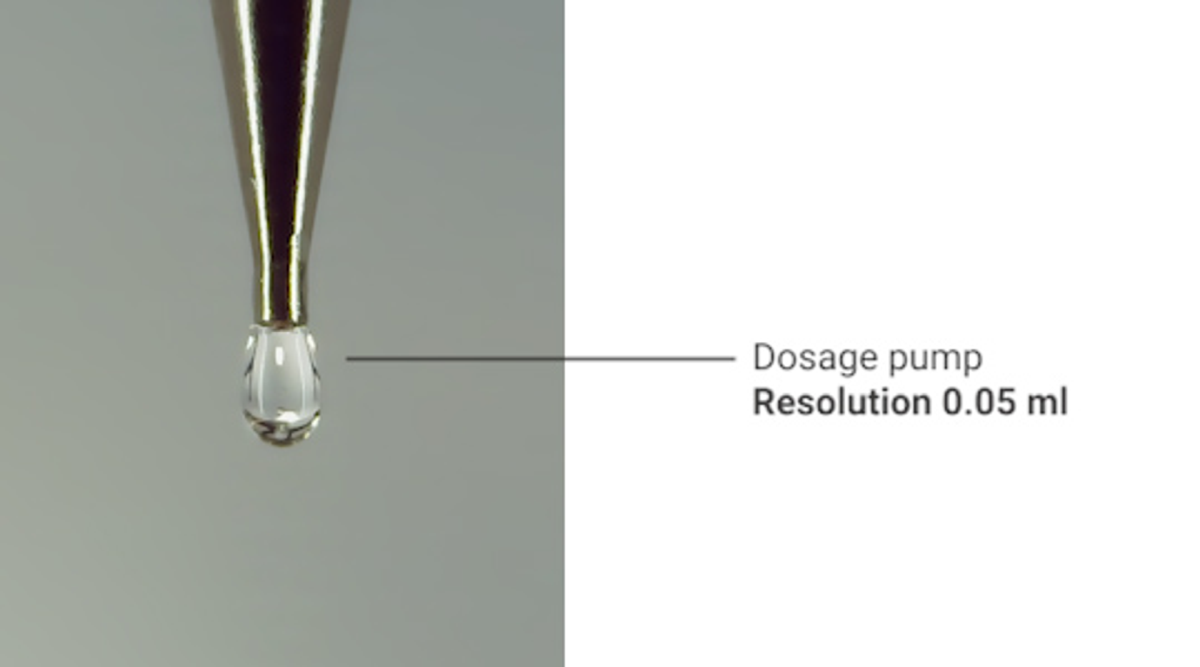

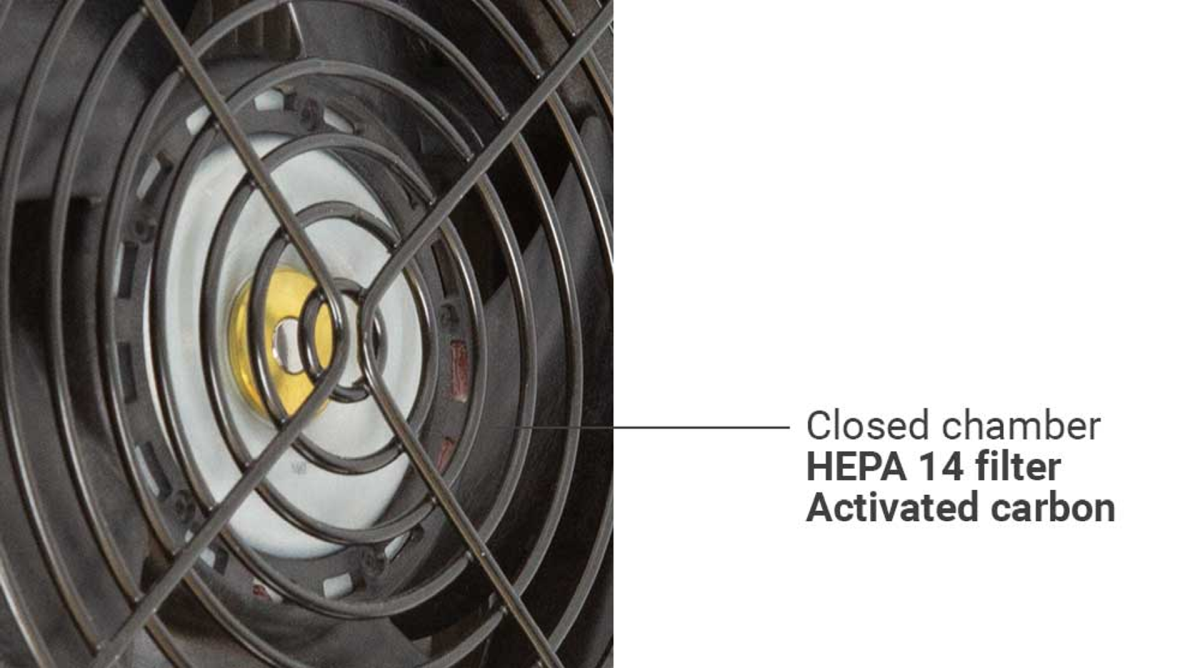

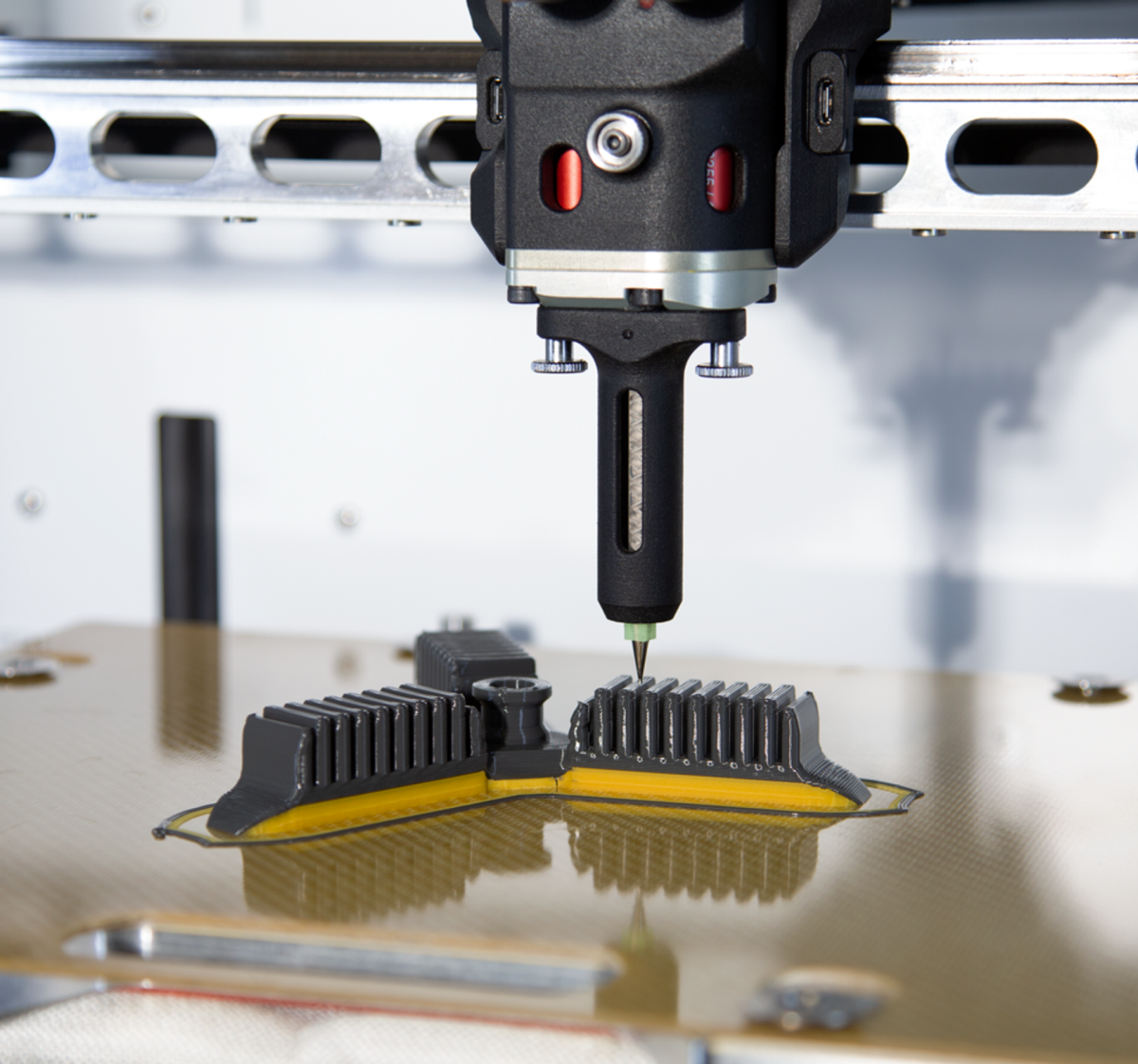

Lynxter introduces the S300X – LIQ21 | LIQ11, an industrial silicone 3D printer that redefines the realm of possibilities. Explore a compact machine, unparalleled reliability, and unprecedented robustness while benefiting from integrated support printing technology for unlimited design potential in medical and industrial silicones as well as polyurethanes.

Lynxter didn’t follow the trend, we started it.

Where others saw limits, we built the machine.

Today Lynxter is at the forefront of silicone 3D printing innovation.

We introduces a new industrial 3D printer, the S300X, the most efficient on the market today to print medical and industrial grade silicones and polyurethanes. A compact, reliable and robust industrial silicone 3D printer with integrated support printing technology for unlimited shape design.